Modelling

Theme Leaders:

Prof. Harry Van den Akker

University of Limerick

Assoc Prof. Damien Thompson

University of Limerick

Modelling platform projects:

Project 5A: Framework for understanding and predicting multi-component solid forms from first principles. Project 5B: Deciphering nanoscale design rules of macromolecular self-assembly. Project 5C: Mathematical modelling of physicochemical processes. Project 5D: Multi-Scale Simulations of Flow and Crystallisation in Industrial Crystallisers.

Overall Objective:

MODELLING addresses the key challenges by developing new techniques to design and predict behaviour in silico in order to reduce trial-and-error experimentation.

Demonstrating expansion of the State of the Art:

- Framework to understand and predict multi-component solid forms from first principles

- Deciphering nanoscale design rules of macromolecular self-assembly

- Mathematical modelling of physicochemical processes

- Multi-Scale Simulations of Flow and Crystallisation in Industrial Crystallisers

Computational Fluid Dynamics techniques provide a better understanding of the dynamics of both the local phenomena and processes (by means of completely resolving them, in DNSs) and the overall flow and mixing behaviour of process equipment (by using advanced models).

Key Scientific Expertise:

The team consists of leading international researchers, with proven expertise, including: synthetic chemistry; flow chemistry; chemical biology; bio-conjugations; hybrid inorganic and organic materials, biological-profiling; bio-inorganic; carbohydrate and automated peptide synthesis; photochemistry; molecular sensors and screening; structural analysis; physico- chemical characterization/analysis; protein expression, purification and modification; proteomics; metal-based drug conjugates, therapeutics and theranostics; imaging agents DNA targeting drugs; fluorescence and cellular/body imaging; material (nano-) chemistry, enzymatic drug activation and release.

Industrial Significance:

Modelling provides the central unifying pillar of Pharm5. By rationally designing from the molecular to materials to macro scale we will dramatically reduce the number of experiments that must be performed to discover and design new molecules, crystals, co-crystals and nanoparticle-enabled deliveries, and to engineer and optimise formulation and processing conditions to deliver new pharma and biopharma solutions.

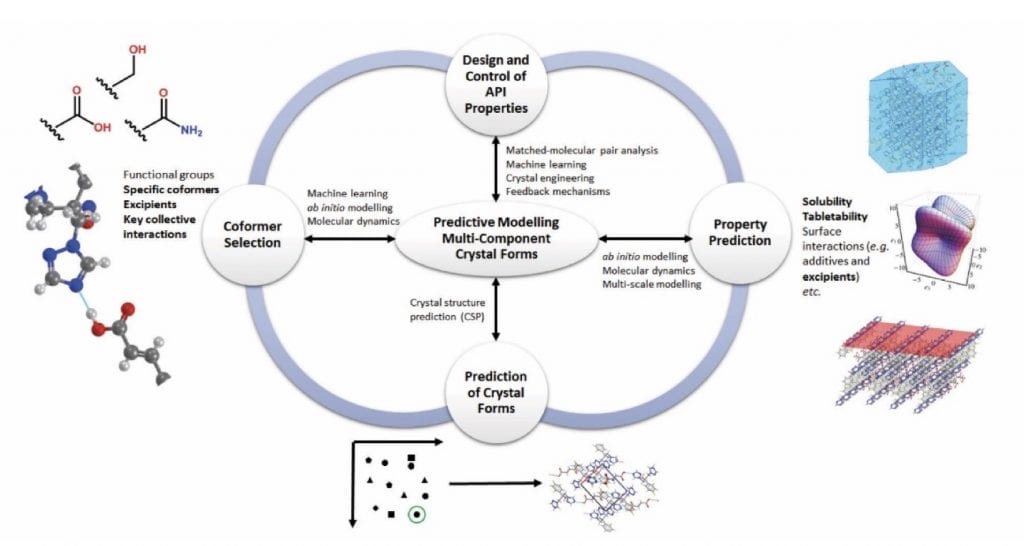

Example project: framework for understanding and predicting multi-component solid forms from first principles

- Employ first-principles modelling to quantify solid-state interactions driving stability of crystals & improve rapid informatics-based approaches to predict likely multi-component solid forms & their properties.

- The platform will push beyond current state of the art by developing new transformative physical models that are sufficiently fast, accurate, and intuitive for broad uptake in drug product manufacture